Canglong Steel structure Co., Ltd in china since 2003

Canglong Steel structure Co., Ltd in china since 2003

Place of Origin | Henan, China (Mainland) |

Standard | GB Standard |

Certificates | CE, ISO9001 |

Grade | Q235/Q355 |

Brand Name | Canglong Group |

Type | Steel Structure |

Surface Treatment | Painted & Hot dip galvanized |

Columns and Beams | H-section Steel |

Purlin | C.Z Shape Steel Channel |

Roof and Wall Panel | Sandwich Panel, Color Steel Plate |

Door | Sliding Door,Rolling Door |

Window | Plastic Steel Window/Aluminum Alloy Window |

Prefab warehouse building is a modern storage solution built in industrialised production mode, which achieves fast delivery and efficient use through prefabricated components in factories and modular assembly on site. Its core lies in the high standardisation of architectural design, component production and construction process, which is suitable for logistics, industry, agriculture, commerce and other diversified scenarios.

Foundation: Reinforced concrete independent foundation or pile foundation is adopted to ensure bearing capacity and stability.

Pre-embedded parts: factory prefabricated steel structure connectors to enhance the precision of on-site installation.

Steel frame: It consists of H-type steel columns, steel beams and purlins, and the main and secondary beams are connected by high-strength bolts to form a large-span space.

Bracing system: horizontal bracing, inter-column bracing and corner bracing enhance the overall wind and seismic resistance.

Metal Roofing: Sandwich colour steel sheet (fireproof rock wool/polyurethane sandwich) + waterproofing membrane, combining heat preservation, waterproofing and durability.

Wall system: sandwich panels or light steel keel partition walls, with optional thermal insulation (EPS/XPS) and ventilated windows.

Polycarbonate lighting panels, fire doors, electric rolling doors, etc. to meet the needs of lighting, ventilation and security.

Reserve pipeline channels for fire sprinkler, electrical wiring, ventilation and air conditioning, etc., and support intelligent upgrading.

Characteristics: sloping roof, light steel frame, suitable for large span (30-60 metres), low-rise warehouses.

Scenario: logistics centre, e-commerce warehouse.

Characteristics: reinforced concrete columns + steel roof frame, suitable for industrial plants with heavy equipment load.

Scenario: machinery manufacturing, automotive repair warehouse.

Features: space truss grid, strong overall rigidity, suitable for complex modelling and large space requirements.

Scenario: cold chain logistics centre, exhibition warehousing.

Characteristics: Light cold-formed thin-walled steel, high modularity, suitable for small and medium-sized warehouses.

Scenario: agricultural products warehouse, community distribution station.

Modular design

Standardised components can be assembled in ‘Lego style’, shortening the construction period by more than 50% (traditional construction takes 6 months, prefabrication takes only 2-3 months).

High-performance structure

High steel strength, seismic grade of 8 degrees, fire performance to meet the GB 51249 standard.

Green Energy Saving

Roof and wall insulation reduces energy consumption by 30%, and the proportion of recyclable materials is over 90%.

Intelligent Compatibility

The reserved IoT interface supports seamless access to AGV logistics robots and temperature and humidity monitoring systems.

You can customize the steel structure in your favorite color, and we will spray paint different colors after the steel structure is processed. Generally, gray is chosen, but red, white, yellow, green, and other colors can also be chosen. The price of steel structures in these colors will be relatively higher. If you are concerned about corrosion, we can choose galvanized steel structures for you.

Logistics Warehousing

E-commerce, express distribution centre: large span + automation to meet the demand for high turnover.

Industrial manufacturing

Auto parts and heavy machinery warehouse: high strength structure is suitable for forklift operation.

Cold chain logistics

Pharmaceuticals, fresh storage: sandwich panel insulation + polyurethane cold storage door, temperature difference control ±2℃.

Agriculture and Cold Chain

Grain reserve warehouse, agricultural storage: ventilation and moisture-proof design + photovoltaic roof energy saving.

Commercial Distribution

Community front warehouses, fresh food supermarkets: modular design adapted to compact urban plots.

Prefabricated warehouse buildings are reconfiguring modern warehousing standards with their industrialised efficiency, flexibility and sustainability. Whether it is to cope with the explosive growth of e-commerce or to upgrade the traditional industrial warehousing, it can provide an integrated solution of ‘rapid deployment, intelligent operation, low cost throughout the life cycle’, which is an ideal choice for industrial upgrading and green building.

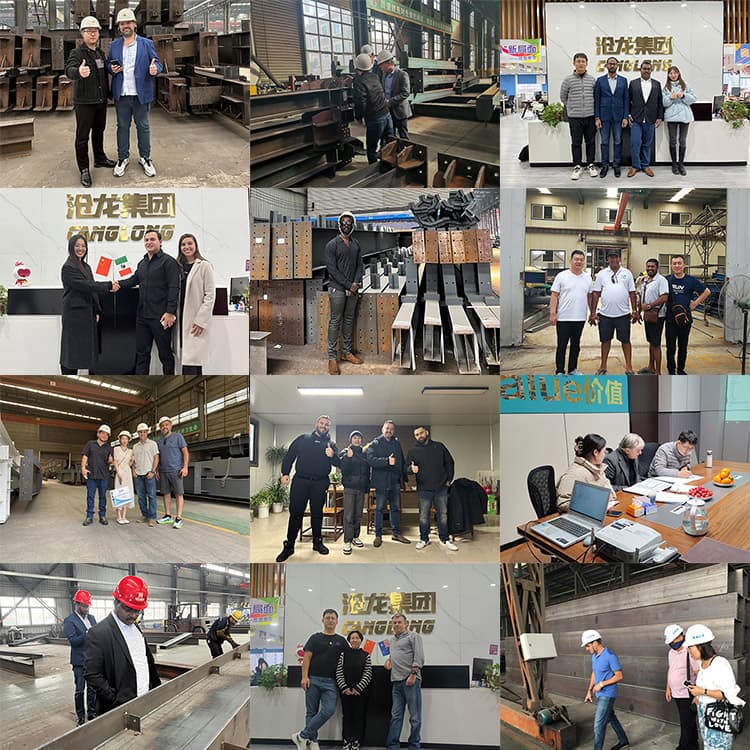

1. Henan Luxury Integrated House Co., Ltd. is the first and largest steel structure & sandwich panels factory in north of China.

2. 20 years experience direct factory with competitive price, stable and controllable quality.

3. Over 100 million dollars of annual output.

4. More than 100000m2 production industrial park.

5. One stop service from design to installation.

6. 10 units free 3D designs & 10 units design structural drawings per day.

7. Professional installation teams in 30+ countries.

8. CE,ISO certificates.

9. Supply quality guarantee for 15 years.

10. Cooperating with 100+ countries & 2000+ partners.

LEAVE A MESSAGE

If you have any questions about our products or services, feel free to reach out to customer service team.

Copyright © 2003-2025 Canglong Steel structure Co., Ltd. | All Rights Reserved