Canglong Steel structure Co., Ltd in china since 2003

Canglong Steel structure Co., Ltd in china since 2003

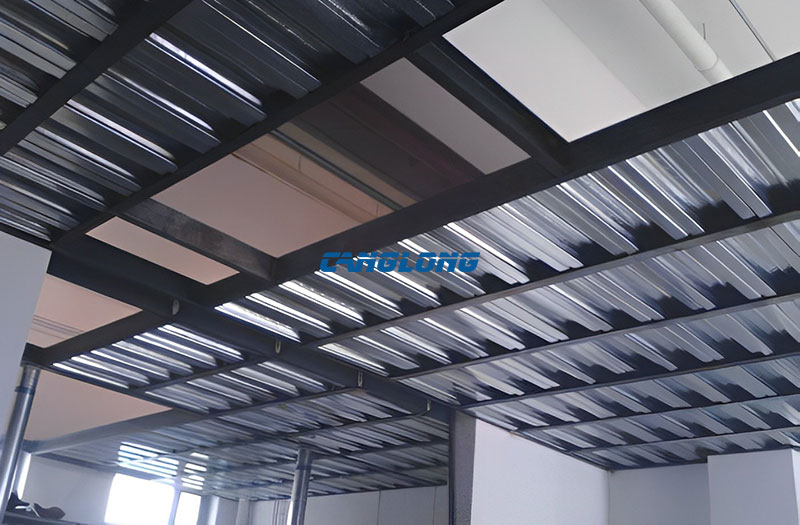

Floor bearing plate is widely used in steel structure engineering industry. As the tensile building reinforcement of concrete floor slab, it not only improves the height width ratio of concrete floor slab, but also saves the use of building reinforcement and concrete, and saves construction time and cost to a certain extent. What are the common problems in the construction of the floor bearing plate of the multistory steel structure workshop?

The construction must be carried out strictly according to the engineering drawings

Before the construction and installation of the floor bearing plate of the multistorey steel structure workshop, the relative plate arrangement drawing shall be drawn, and the construction shall be carried out according to the engineering drawings. The floor bearing plate shall be paved from one end of the floor slab, and the parts shall be adjusted and fixed while paving. The floor bearing plate shall be installed first in the area where there is a hole, and then the hole size shall be laser cut according to the specific hole location.

Special attention shall be paid to the construction of stud

The stud is a connecting piece between the floor beam and the concrete floor slab of the concrete structure to form a connection effect. For the construction of stud in the multistory steel structure workshop, arc type stud welding machine and welding gun shall be selected, and deoxidized arc high temperature resistant porcelain shall be used to sit in the seat ring.

Electric welding method of stud

In the multi-layer steel structure workshop, the stud welding process is first connected to the switch power supply of the welding gun of the second shield welding machine, and the column stud is sleeved on the welding gun. The anti arc setting ring starts the welding gun, and the current will melt off immediately, while the setting ring will cause electric light. After a short period of time, attach importance to the stud, tighten the butt weld at a certain rate to melt, disconnect the switching power supply, and fix the column stud on the butt weld.

After the electric welding is carried out, the quality shall be inspected, and the surface inspection of hammering dominant appearance shall be taken as the guidance. If there is a gap in the welding, the stud shall be scrapped, and one stud must be welded around again.

LEAVE A MESSAGE

If you have any questions about our products or services, feel free to reach out to customer service team.

Copyright © 2003-2025 Canglong Steel structure Co., Ltd. | All Rights Reserved